Harsh Environments

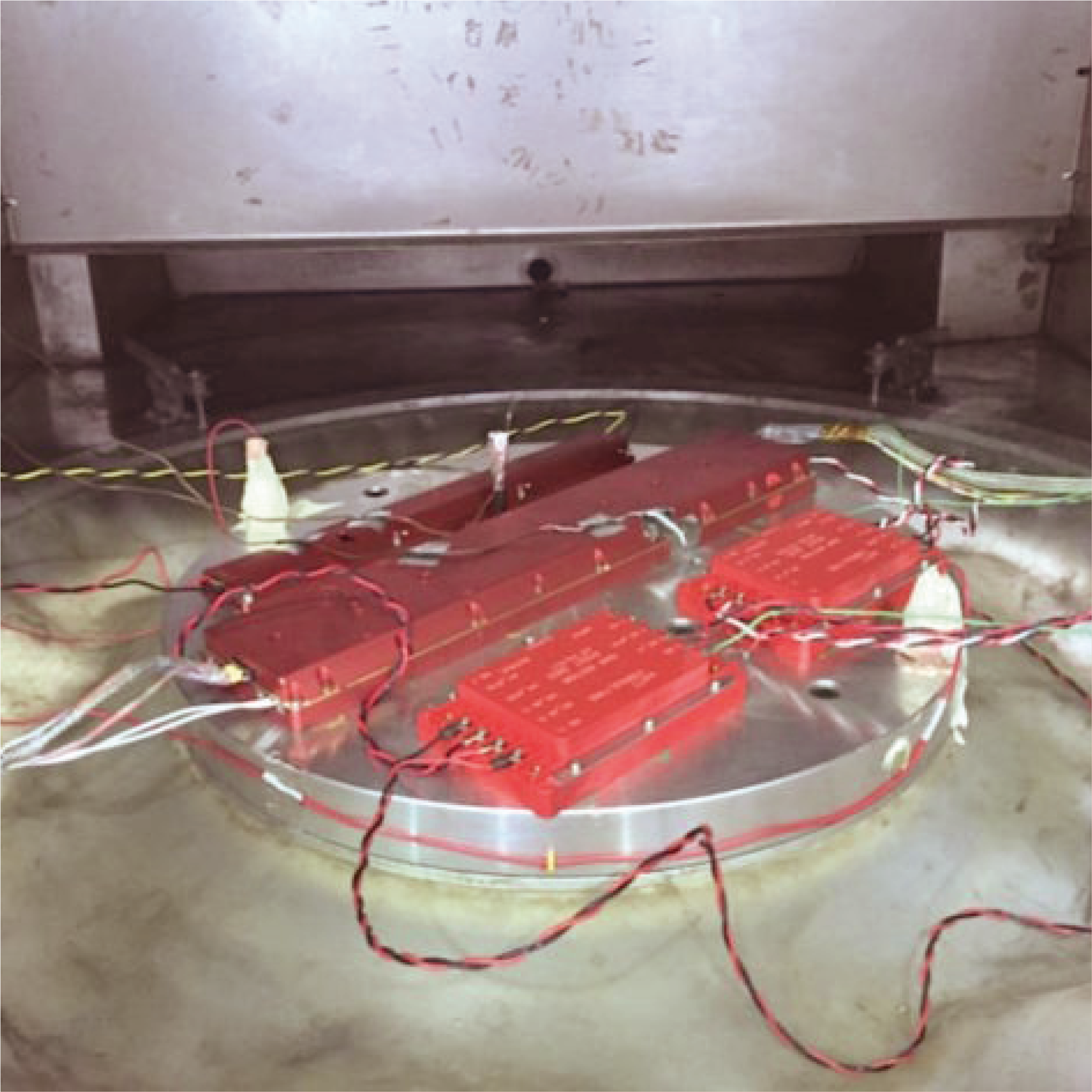

We are experts in harsh environment power electronics. We can develop and optimize power converters to work at extreme temperatures (from -40 °C to 220 °C) and high shock and vibration levels. We design our own magnetics, fitting downhole environments and form factors. We use high temperature electronics technologies (SOI for instance), but also industrial standard technologies (Si and SiC) for the best cost, temperature control and lifetime compromise. We master assembly and packaging techniques for temperature, shock and vibration hardening.

Our product range is designed and qualified for typical downhole environment (150-175°C ambient temperature) and offers simple system architecture, and small and light power modules combined for easy system integration.

Do you need a customization? Our extensive library of electronics and magnetic components made to perform within harsh environments allows us to design and prototype at a short notice, so your time-to-market will be reduced.

Motor Control

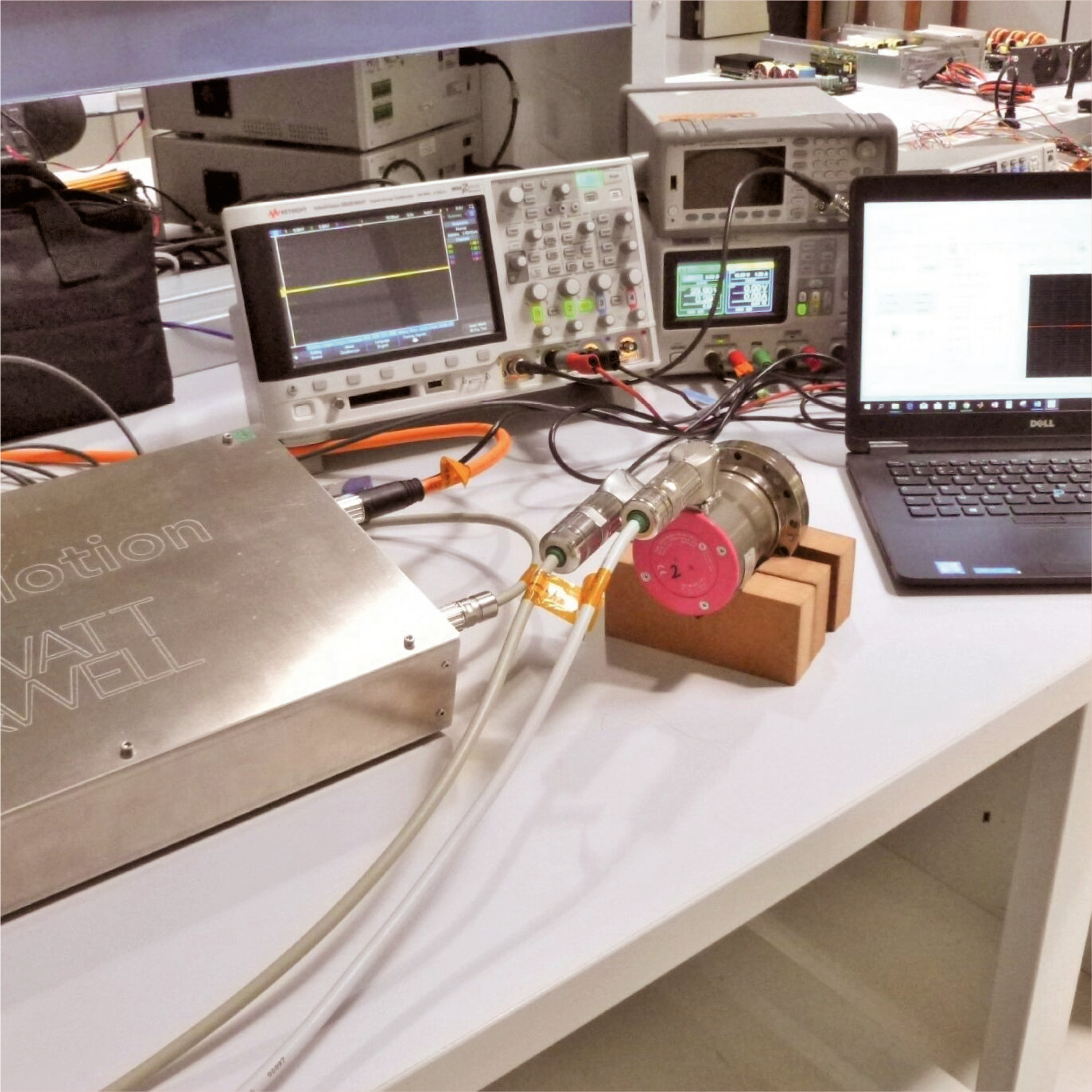

Watt & Well engineers have worked on motor control drivers for more than 10 years. We developed and mastered our own simulation models for motors and inverters, our own control algorithms and our own power stage designs.

Our motor control drivers are designed to drive Permanent Magnet Synchronous Motors (PMSM), Brushless Direct Current (BLDC) motors and asynchronous motors, for a nominal power that ranges from a few watts to several kilowatts. They can operate with resolver or hall effect sensors, and without a sensor, in sensor-less mode.

Depending on the application requirements, our motor controllers can be easily configured to select the operating mode: motor shaft position regulation, speed regulation, torque regulation if Field Oriented Control is included, power regulation or DC voltage regulation if the machine is in electric power generator mode.

We extensively use sophisticated digital control for efficient, connected and customizable solutions.

A variety of motor controllers are available, covering a wide range of power and voltage. We can customize an existing product to fit your requirements if necessary.

Power Supply

We have the skills to design your power supply: topology selection, galvanic insulation or not, analog or digital control, form factor, magnetic design, control algorithm design.

We are familiar with the downhole constraints that makes the conception difficult: temperature, shocks, vibrations, form factor.

Our experience in power electronics, magnetic components and efficient thermal management enables us to provide best-in-class power supplies and innovative, compact and cost effective solutions.

Besides providing you with a range of off-the-shelf power supplies, we also design tailor-made solutions to best fit your needs.

System Integration

We consider power electronics subsystems to be a vital parts of the global system. Our job is not done until our converters or motor controllers are efficient and reliable once following integration into tool. We plan for the integration phase to be as smooth as possible.

We investigate the effects on the system of each of our subsystem performances. To achieve these goals, most of our products are based on a digital core with CAN bus communication to complete performance monitoring, system configuration, real-time tuning of the converter or the motor driver control algorithm.

At the earliest phase of the project, we are able to make a complete simulation model of the provided product and the related tool subsystem ensuring a better understanding of effective product performances and limitations. It also provides the project team with coherent specifications of their power sub-system prior to the new products’ development.